IATF 16949 is the global quality management standard for the automotive supply chain. Built on ISO 9001, it adds automotive-specific requirements such as APQP/PPAP, FMEA, MSA, SPC, traceability, and defect prevention. If you’re sourcing stamped sheet-metal parts, welded assemblies, or tube-formed components, IATF compliance is the fastest way to reduce risk on quality, delivery, and cost of poor quality.

What IATF 16949 Actually Covers

- Process approach & risk-based thinking: map processes, KPIs, risks, and controls.

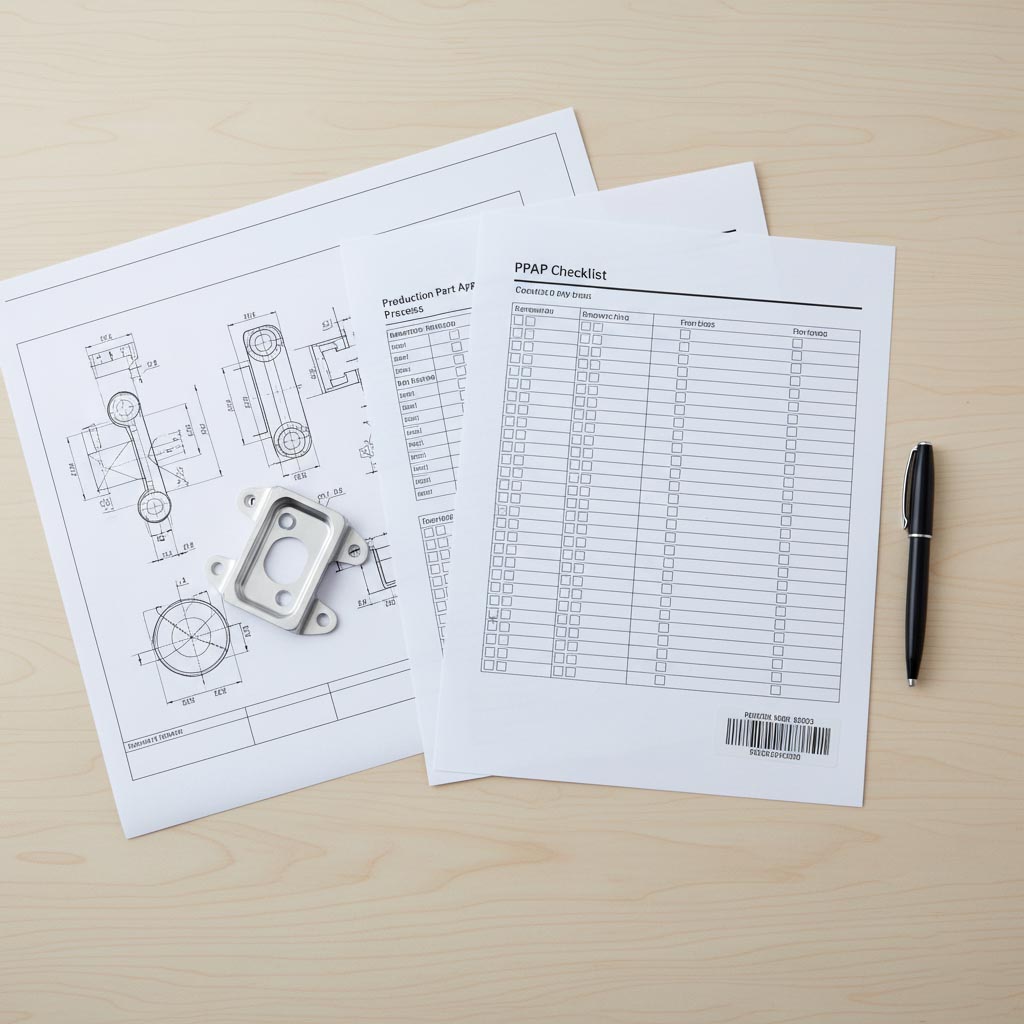

- APQP & PPAP: structured launch and Production Part Approval with evidence.

- FMEA: DFMEA/PFMEA to identify failure modes and prevention plans.

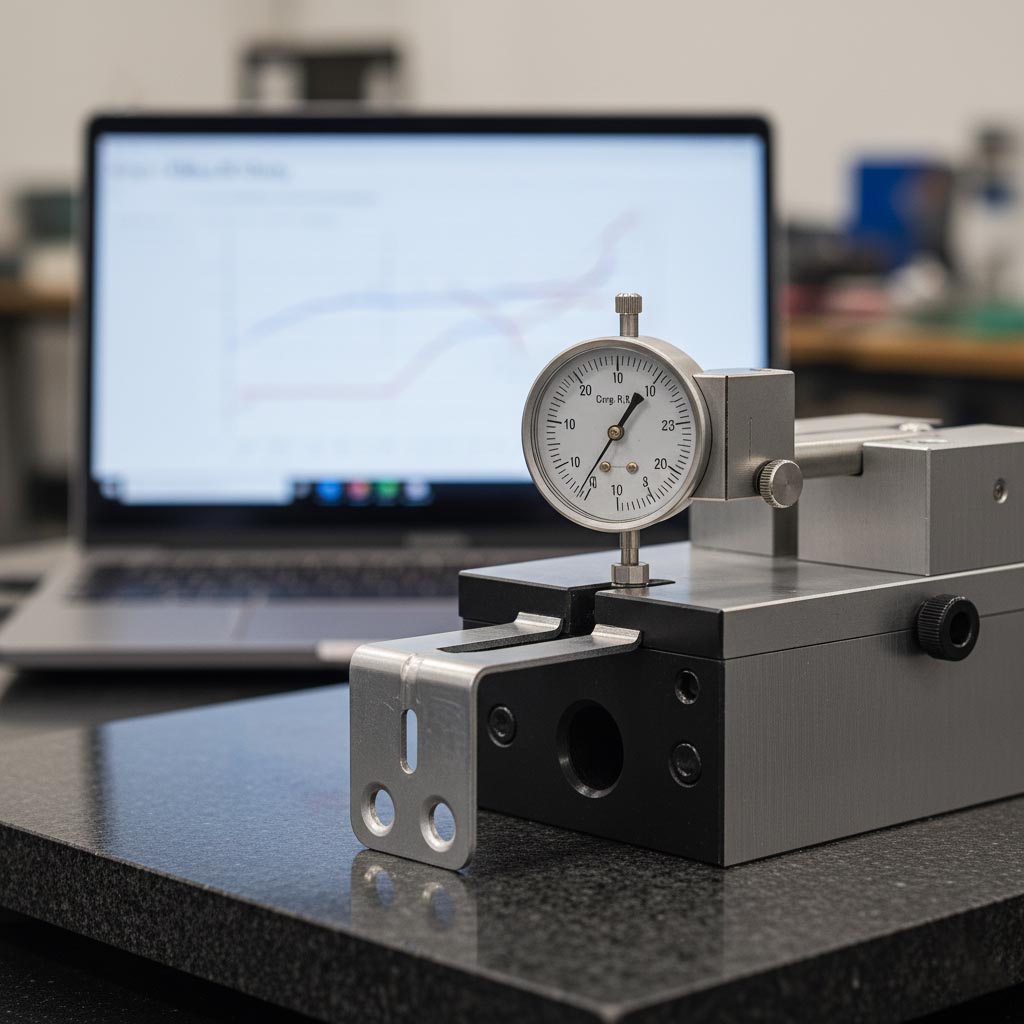

- MSA & SPC: gage studies (GR&R) and process capability (Cp/Cpk, Pp/Ppk).

- Control plans & work instructions: how the part is consistently built and checked.

- Traceability & change control: lot/material certs, ECN control, and run-at-rate.

- Non-conformance & 8D: containment, root cause, corrective & preventive actions.

- Supplier management: cascading requirements to sub-suppliers and monitoring.

Why It Matters to Buyers

| Fewer Launch Issues | APQP & PPAP catch risks before SOP; less firefighting and rework. |

| Predictable Quality | SPC/Capability targets keep dimensions in control across batches. |

| Traceability | Lot/material certs and labels simplify investigations & recalls. |

| Lower Total Cost | Prevention beats inspection—fewer defects, delays, and chargebacks. |

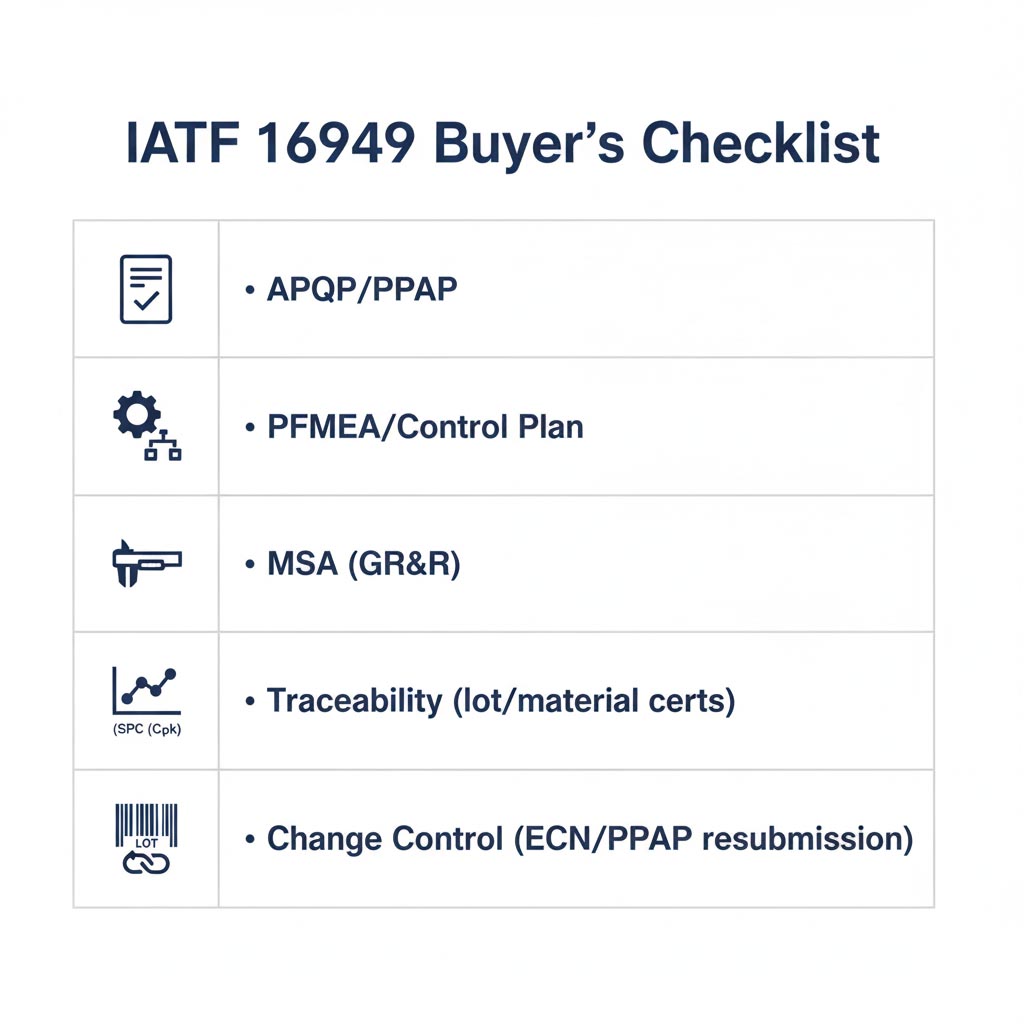

Quick Buyer’s Checklist (Request These in Your RFQ)

- IATF certificate: supplier name/site address, scope includes manufacture of auto components, current issue & expiry, accredited certification body.

- APQP plan & timeline: gateways, run-at-rate, PPAP submission date.

- PPAP level & samples: Level 3 by default unless agreed; sample quantity and packaging validation.

- PFMEA & Control Plan: latest revision with linked characteristics and gauges.

- MSA & Capability: GR&R for critical gauges; initial Cp/Cpk/Ppk targets on CTQs.

- Traceability: lot numbering scheme, barcoded labels, material test certificates.

- Change control: how ECNs, tool repairs, or supplier changes are approved and recorded.

- Contingency plan: power/tooling breakdown, alternate materials, disaster readiness.

- Sub-supplier control: how steel/coating/tube vendors are qualified and monitored.

How to Verify a Supplier’s IATF 16949 (Fast)

- Certificate check: name, address, scope, valid through date, and accreditation logo.

- Ask for last audit summary: major/minor NCs and closure evidence.

- Sample docs: one PFMEA page, one control plan page, one GR&R, one capability study.

- Shop-floor evidence: gauge calibration stickers, traceability labels, work instructions at the cell.

- Run-at-rate data: cycle time, OEE snapshot, scrap/PPM trend for a similar part.

Common Red Flags During Supplier Vetting

- Certificate scope excludes automotive manufacturing or lists a different site.

- PFMEA/control plan don’t reference the same special characteristics as the drawing.

- No GR&R for critical gauges; capability reported without raw data.

- Traceability limited to invoices only (no lot/batch labels on parts or cartons).

- Informal change handling (tool repairs or material switches without PPAP resubmission).

Sample RFQ Language You Can Copy

Supplier shall maintain a certified IATF 16949 quality management system for the quoted site. Submit APQP plan, PPAP Level 3 (unless otherwise approved), PFMEA, Control Plan, GR&R studies for critical gauges, initial capability (Cp/Cpk ≥ 1.33) on CTQs, traceability scheme (lot/material certs), and packaging validation prior to SOP. Any product/process/material change requires prior written approval and PPAP resubmission.

How SGI Automotive Helps

SGI manufactures OEM-grade sheet-metal press parts, welded assemblies, and tube-formed components. We support APQP/PPAP, provide full lot traceability and material certificates, and share capability/MSA data during validation. Ask us about fast-track PPAP and consolidated packaging for export programs.