The Future of Automotive Components: EVs, Hybrids & Beyond

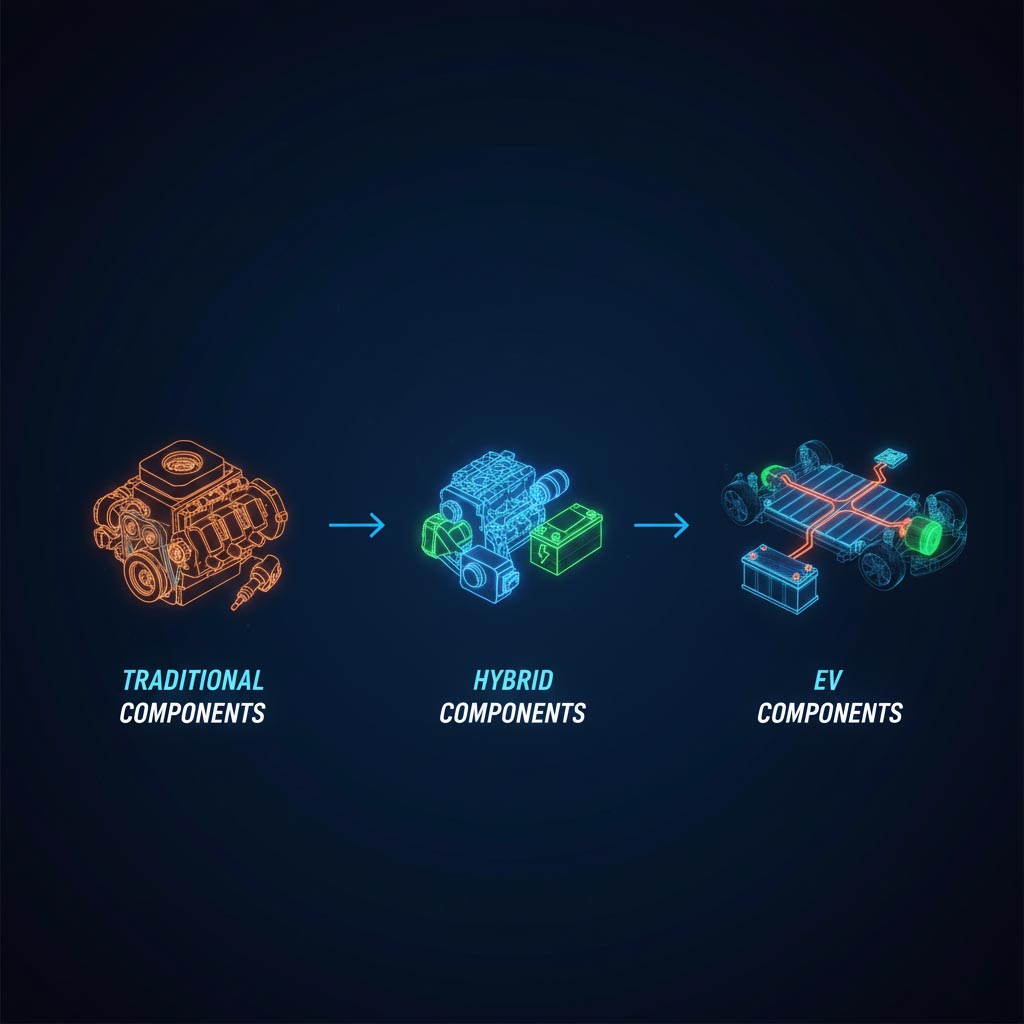

Electrification is turning vehicles into software-defined machines. Batteries replace fuel tanks, motors replace engines, and controllers coordinate energy, safety, and diagnostics. As EV and hybrid adoption accelerates, the components that matter—and how they are designed, validated, and manufactured— are changing fast. Here are the subsystems to watch and what it means for suppliers.

Core Systems in EVs & Hybrids

- Electric Motor + Inverter: High-efficiency motors with SiC/GaN inverters enable compact drive units and rapid charging at 800V.

- On-Board Charger & DC/DC: Efficient AC conversion and HV→LV step-down for auxiliaries and redundancy.

- Thermal Orchestration: Cooling plates, valves, and heat pumps regulating packs, power electronics, and cabin comfort.

- ECUs & Software: Domain/zone controllers, secure OTA, and data logging—turning vehicles into upgradable platforms.

- Lightweight Structures & HV Harness: Composites, aluminum, shielded HV connectors, and service-friendly routing.

Near-Term Innovations (2025–2030)

- 800V Architectures: Lower current, thinner cables, and ultra-fast charging with SiC power modules.

- Integrated Drive Units: Motor, inverter, and gearbox packaged together to reduce mass, losses, and cost.

- Unified Thermal Loops: One system conditioning packs, power electronics, and cabin with heat pumps.

- Battery Chemistry: High-silicon anodes and early solid-state pilots for higher energy density and safety.

- Recycling & Second-Life: Closed-loop materials and stationary storage to improve lifetime economics.

- Cybersecurity & OTA: ISO 21434, secure boot, and continuous feature updates by default.

What This Means for Suppliers

Quality & Safety: IATF 16949, ISO 26262, PPAP/APQP, and full traceability across HV components are non-negotiable.

Materials & Metrology: Tight tolerances for cooling plates, busbars, insulation; dielectric, leak, burst, and NVH tests at EOL.

Design Collaboration: Co-development for DFM/DFA, rapid tooling changes, and validation cycles aligned with software releases.

Key Takeaways

- Value is shifting toward power electronics, thermal systems, batteries, and software.

- 2025–2030 brings 800V mainstreaming, integrated drive units, smarter thermal control, and stronger cybersecurity.

- Suppliers win with quality systems, traceability, safety compliance, and fast co-development.