When you source components for a vehicle program, understanding the difference between OEM and aftermarket parts is critical. For stamped sheet-metal parts, welded assemblies, and tube-formed components, the choice affects safety, warranty, cost, and lead time. This guide explains both options and shows when to specify OEM-grade for reliability.

OEM Parts — What They Are

OEM (Original Equipment Manufacturer) parts are built to the vehicle maker’s exact drawings and specifications, using approved materials, processes, and quality plans. They are validated through PPAP/APQP and are fully traceable by lot and revision. Typical use cases: new model launches, service parts under warranty, safety-critical brackets, body-in-white reinforcements, seat structures, exhaust hangers.

Aftermarket Parts — What They Are

Aftermarket parts are made by companies other than the vehicle’s OEM, matching the general fit and function of the original. Tolerances and process controls may vary by brand. Great for cost-sensitive replacements, fleet maintenance, and non-safety critical applications, provided fit, durability, and compliance are verified.

Key Differences at a Glance

| Dimension & Tolerance | OEM holds drawing GD&T ± as specified and capability (Cp/Cpk) targets; aftermarket varies by maker. |

| Validation | OEM requires APQP/PPAP, MSA, control plan; aftermarket may use internal FAI without PPAP. |

| Traceability | OEM full lot & material certs; aftermarket traceability ranges from good to minimal. |

| Cost | OEM usually higher (tooling, validation). Aftermarket tends to be lower at volume. |

| Lead Time | OEM includes die build, run-at-rate, PPAP. Aftermarket can be faster for existing tooling. |

| Warranty & Compliance | OEM protects warranty and regulatory compliance; aftermarket must be vetted per market. |

When to Specify OEM-Grade Parts

- Safety-critical brackets, seat and restraint components, body structural parts.

- Programs under OEM warranty or homologation requirements.

- Where NVH, corrosion, or fatigue life is tightly specified.

- Assemblies requiring tight stack-up control or robot weld fixtures.

Aftermarket is Sensible When…

- Fleet maintenance needs cost-effective replacements for non-safety-critical parts.

- Legacy models where the OEM no longer supplies service components.

- Customization where the spec prioritizes price/availability over OEM validation.

Buyer Checklist (Use This in Your RFQ)

- Part intent: OEM program / service part / aftermarket.

- Drawings & GD&T: latest revision, critical dimensions, gauges.

- Material: grade & thickness (with substitutes if allowed).

- Process: press tonnage/stages, weld type (spot/MIG/TIG), tube bend specs.

- Quality: IATF 16949/ISO status, control plan, PPAP level, Ppk targets.

- Volume & MOQ: annual usage, batch size, ramp plan.

- Compliance: coatings, corrosion tests, RoHS/REACH as applicable.

- Logistics: Incoterms, packing, labels, palletization, traceability.

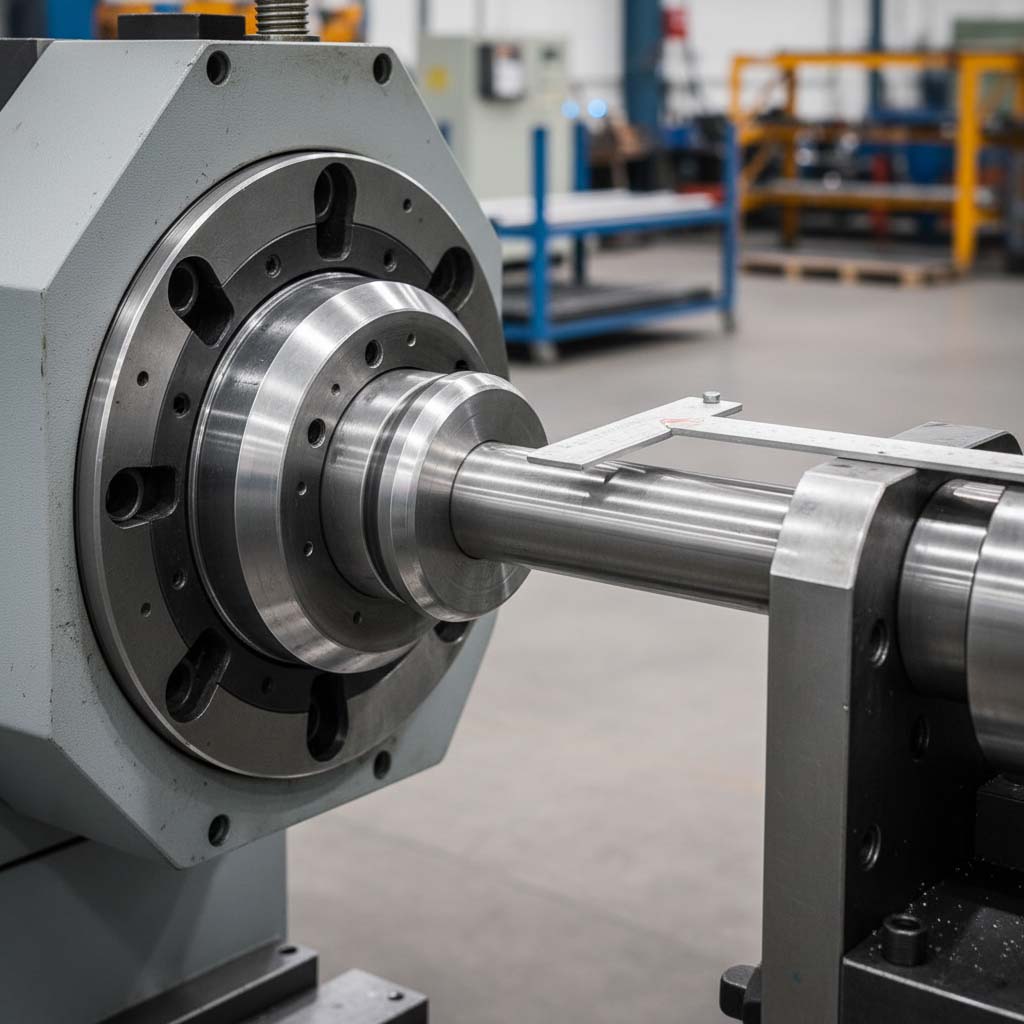

How SGI Automotive Helps

SGI manufactures OEM-grade sheet-metal press parts, welded assemblies, and tube-formed components. We support APQP/PPAP, provide full lot traceability and material certs, and can localize tooling for export programs. For aftermarket buyers, we offer engineering support to align fit, finish, and durability with your target price.